Imagine a space so pristine and controlled that even a single particle of dust could cause catastrophic consequences. This is the essence of a clean room—an environment designed to maintain extremely low levels of contaminants to safeguard sensitive processes and delicate equipment. This article will explore the fascinating world of clean room design, discussing its importance, key considerations, and the meticulous planning involved. So, let’s dive in! The content is collaborated with https://newark67.com/

Introduction to Clean Room Design

What is a Clean Room?

Clean rooms are specialized facilities that maintain controlled environments to minimize the presence of airborne particles, dust, microbes, and other contaminants. These rooms are crucial in pharmaceuticals, biotechnology, electronics, healthcare, and manufacturing industries, where even the tiniest impurities can compromise product quality, research outcomes, or patient safety. You may also be interested in building a cleanroom.

The Significance of Clean Room Design

Clean room design plays a pivotal role in ensuring the success and reliability of critical operations. By providing a controlled environment, clean rooms offer the following benefits:

- Contamination Control: Clean rooms prevent the ingress of contaminants, safeguarding products, equipment, and processes from potential damage or failure.

- Quality Assurance: Maintaining strict control over environmental parameters helps achieve consistent product quality and reliability.

- Regulatory Compliance: Various industries have stringent regulatory requirements, and adherence to clean room standards is often mandatory for compliance.

- Safety and Health: Clean rooms create a safe environment for personnel working with hazardous materials or processes, protecting them from potential exposure.

Key Considerations in Clean Room Design

Designing an effective clean room requires a comprehensive understanding of the specific requirements and challenges of the intended application. Let’s explore some key considerations that need to be addressed during the design process:

1. Cleanliness Classification and Standards

Cleanliness classifications are defined by international standards such as ISO 14644-1. These standards specify the maximum allowable particle concentration per cubic meter of air, based on particle sizes. The clean room’s classification determines the level of cleanliness required for the specific application and guides the design process.

2. Airflow and Ventilation Systems

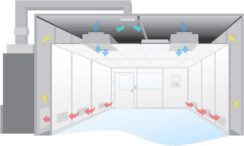

Airflow and ventilation systems are critical components of clean room design. Proper air circulation, filtration, and pressure differentials help control the movement of particles and contaminants. Techniques such as laminar flow, high-efficiency particulate air (HEPA) filters, and controlled air exchanges are employed to maintain the desired air quality.

3. Temperature and Humidity Control

Temperature and humidity control are essential for certain clean room applications. Precise regulation of these parameters ensures optimal conditions for processes and equipment. Cooling systems, humidity control devices, and insulation techniques are employed to maintain stable and controlled environments.

4. Material Selection and Surface Finishes

Materials used in clean room construction must be carefully selected to minimize particle generation and facilitate easy cleaning. Non-shedding and low-emitting materials, such as stainless steel and specialized coatings, are commonly employed. Smooth and impervious surface finishes prevent particle accumulation and facilitate decontamination.

5. Contamination Prevention Measures

Apart from the physical design aspects, additional contamination prevention measures are employed. These include proper gowning protocols for personnel, rigorous cleaning and disinfection procedures, and the use of specialized equipment and tools that minimize particle generation.

Conclusion

Clean room design is an intricate process that requires meticulous planning, adherence to standards, and a deep understanding of the specific requirements of the intended application. By providing controlled environments, clean rooms ensure the integrity, reliability, and safety of critical operations across various industries. Whether it’s manufacturing life-saving medications or conducting cutting-edge research, the significance of clean room design cannot be overstated.

FAQs (Frequently Asked Questions)

What are the main industries that utilize clean rooms?

Clean rooms are extensively used in industries such as pharmaceuticals, biotechnology, electronics, healthcare, and manufacturing.

What is the purpose of maintaining low particle levels in a clean room?

Low particle levels ensure the protection of sensitive processes, equipment, and products from potential contamination, which could lead to product failures or compromised research outcomes.

What are some common challenges in clean room design?

Some common challenges include achieving the desired cleanliness classification, ensuring proper airflow and ventilation, maintaining temperature and humidity control, and selecting appropriate materials and surface finishes.

How are clean rooms regulated and monitored for compliance?

Clean rooms are regulated and monitored through international standards, industry-specific guidelines, and routine inspections by regulatory bodies. Regular particle count monitoring and air quality testing are also performed.

Can clean room design be customized for specific applications?

Absolutely! Clean room design is highly customizable and tailored to meet the specific requirements of different applications, ensuring optimal performance and adherence to industry standards.