Having your furnace fan not turn on when it should be can be frustrating and concerning. However, several potential causes for this issue can often be addressed relatively quickly. In this guide, we’ll walk through the common reasons a furnace fan fails to start and provide tips on how to get it working again.

How Does a Furnace Fan Work?

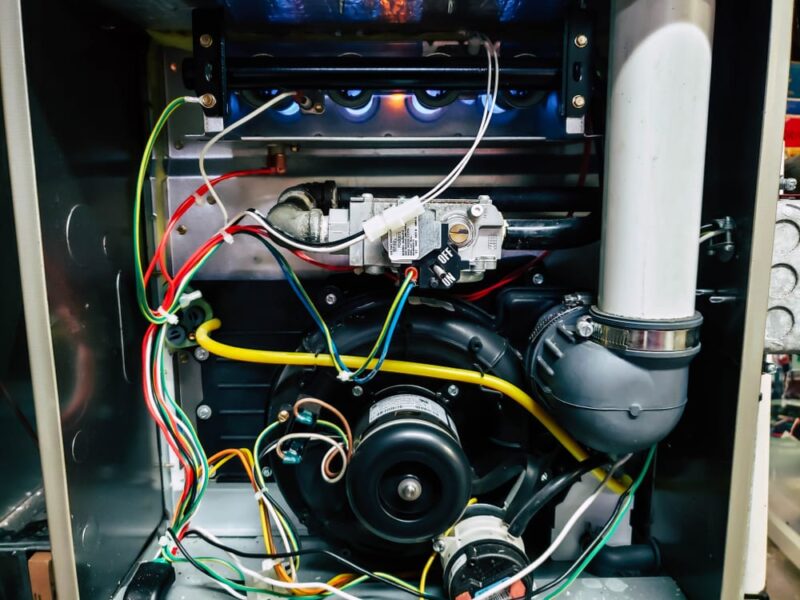

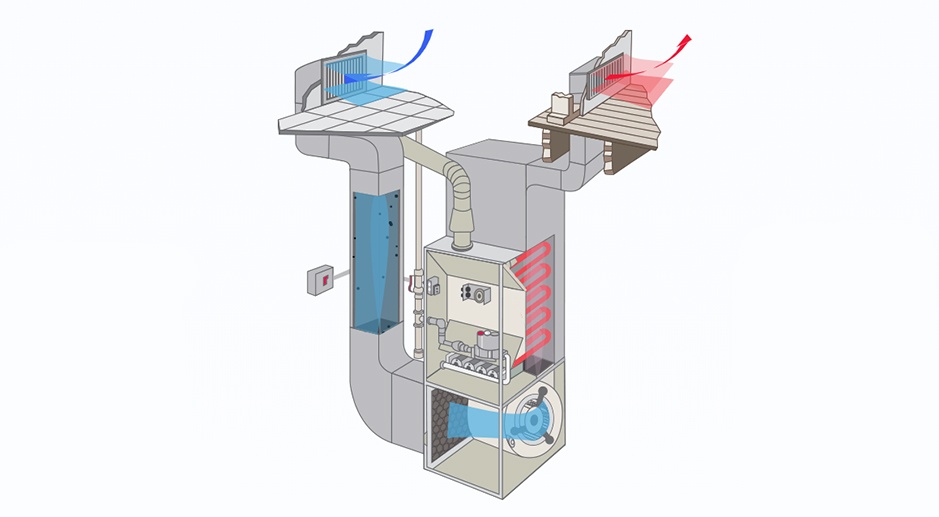

Before diving into furnace fan troubleshooting, it helps to understand what the fan does and how it operates in a furnace system.

The furnace fan is responsible for circulating air in your home’s ductwork. It typically runs with your furnace’s burner to distribute warm air during the heating season. However, it also runs independently of the burner during continuous fan mode.

This mode is handy when you want to maintain a consistent airflow throughout your home, even when the furnace is not heating. Many homeowners wonder whether leaving the furnace fan on or auto in winteris more efficient. The decision depends on various factors, such as your comfort preferences, energy efficiency goals, and the overall performance of your heating system.

There are a couple of different fan configurations found in furnaces:

- Belt-driven fans utilize a motor connected via a belt to spin the blower wheel. The motor receives electrical power and converts it to mechanical energy to turn the fan.

- Direct-drive fans – The blower wheel is mounted directly to the motor shaft. So when electrical power spins the motor, it turns the fan at the same time.

The furnace control board controls the furnace fan. This board gets signals from the thermostat and furnace components to know when to turn the fan on and off.

During a call for heat

- The thermostat sends power to the control board, signaling a need for heat.

- The control board activates the ignition process to light the furnace burner.

- After ignition, a pressure switch or sensor confirms the burner is on.

- The control board then sends electrical power to the fan motor to start the blower.

This process circulates warm air from the heat exchanger through your ducts. The fan typically runs a few minutes after the burner shuts off to extract leftover heat.

So, in summary, the furnace fan relies on proper electrical control signals and a functioning motor/belt to start up when needed. With that foundation, let’s explore why it may not be coming on.

6 Common Reasons a Furnace Fan Won’t Start

There are a variety of possible culprits if your furnace fan isn’t kicking on appropriately:

1. Power Supply Issues

Like most furnace components, the fan motor receives electrical power to run. So power issues are one of the most common reasons a furnace fan won’t start up.

Here are some power-related problems that could prevent the fan from turning on:

- Blown fuse – Most furnace control boards have a fuse to protect the fan motor circuitry from power surges. If this fuse blows, it interrupts the power supply to the motor.

- Tripped circuit breaker – The circuit breaker providing power to the furnace could trip, cutting off electricity to the fan motor.

- Faulty control board – If it has issues with its transformer or relay, it may not send power to the fan when needed.

- Faulty blower motor – Problems with the motor windings can prevent it from receiving electricity properly.

- Loose wiring connections – Electrical connections to and inside the blower motor can vibrate loose over time. This interrupts the power supply.

If the fan motor isn’t receiving proper electrical power, it won’t be able to start. Checking for power issues is one of the first steps in diagnosing a non-working furnace fan.

2. Seized Bearings or Stuck Pulley

In belt-drive furnace fans, worn bearings or stuck pulleys can prevent the blower wheel from spinning correctly.

The bearings allow the motor shaft and blower pulley to rotate smoothly. If the bearings seize up from lack of lubrication or wear, it will put extra drag on the motor. A motor with seized bearings may hum but not have enough torque to start the blower wheel spinning.

Similarly, if the blower pulley seizes in place, it won’t allow the belt to spin the blower. Pulleys can rust in place if moisture gets into the furnace, preventing rotation.

They are checking that the motor shaft and blower wheel turn freely, an important maintenance step. Binding bearings or pulleys could be the culprit if they don’t spin easily.

3. Broken Fan Belt

With belt-drive furnace blowers, a broken or slipping belt can prevent the fan from turning.

The belt connects the motor pulley to the blower wheel pulley. The connection will be lost if it breaks, and the blower won’t start. Belts can wear out from age and eventually snap.

Low belt tension can also cause slippage, especially when starting under load. The belt needs sufficient tension to grip the pulleys firmly to transmit rotational force. A loose belt may slip on startup, not allowing the blower wheel to turn.

Inspecting the belt and checking tension is a quick way to determine if a belt issue is causing problems. Most furnace belts are inexpensive and easy for a handy homeowner to replace.

4. Blocked Airflow

For the furnace fan to start up and run properly, it needs adequate airflow. Restricted airflow from ductwork issues can strain the blower motor excessively, preventing startup.

Some examples of airflow restrictions include:

- Dirty air filters

- Blockages in ducts from debris or kinked flexible ducts

- Closed registers or dampers

- Excess lint buildup around the blower wheel

- Improperly sized ductwork

The increased workload from pushing air through excessive blockages can hinder the motor. In severe cases, it may strain to start and run, overheat, and eventually fail to start altogether.

Inspecting for airflow restrictions is worthwhile if the fan won’t run. Often, cleaning filters, removing debris, and adjusting dampers can get things flowing freely again.

5. Faulty Fan Control

As outlined previously, the furnace control board dictates when power is sent to the fan motor based on thermostat signals and furnace conditions. Problems with the control board fan relay or pressure switch could prevent the fan from starting up when needed.

If the fan relay malfunctions, it may not send electricity to the motor when heat is required. The pressure switch confirms the burner is on before engaging the fan. So if the pressure switch fails, the board won’t get the signal to start the fan.

Fan control failures can be difficult to isolate without advanced electrical testing equipment. A technician can diagnose wiring issues or control board problems affecting fan operation. If the fan runs during testing but not in regular operation, fan controls are the likely culprit.

6. Faulty Blower Motor

Of course, the blower motor may fail and no longer start when power is applied. Motors have electrical windings and bearings that wear over years of cycling on and off. Eventually, these components degrade enough to cause failure.

Warning signs of a failing motor include:

- Slow starting/not turning at full speed right away

- Humming noise but not starting

- Intermittent operation – starts sometimes but not others

- Overheating and burning smell

- Unusual noises like squealing or grinding

If the motor shows these symptoms, it likely needs professional replacement. Technicians have specialized tools to test furnace motors and fans appropriately for functionality.

Furnace Fan Troubleshooting Steps

Now that we’ve covered the most common furnace fan problems let’s go through a systematic troubleshooting process to isolate what’s preventing a start:

Step 1:

Confirm the thermostat is calling for heat and power is supplied to the furnace. Turn the thermostat to a temperature above the room temperature. Verify the thermostat is wired correctly, and the stove receives power (control board display is on, etc.)

Step 2:

Check for any blown fuses or tripped breakers supplying power to the furnace. Reset any tripped breakers and replace any blown fuses.

Step 3:

Inspect the fan belt (if belt-driven). Look for broken belts, excessive wear, and proper tension. Replace if broken and adjust tension if loose.

Step 4:

Test that the blower wheel spins freely by hand. Seized bearings or stuck pulleys will need to be addressed.

Step 5:

Remove the blower compartment door and visually inspect for debris buildup. Use a vacuum to clean out any dirt or lint accumulation.

Step 6:

Check filters and ducts for blockages. Replace dirty filters and remove any debris/obstructions in the ductwork.

Step 7:

Observe furnace operation as heat is called for. Listen and look for the ignition sequence to start. The fan should turn on after the burners ignite. If the fan doesn’t start, faulty controls are likely preventing operation.

Step 8:

Inspect all wiring thoroughly. Secure any loose connections leading to the fan motor.

Step 9:

Have a professional technician evaluate the fan motor, controls, and electrical circuits. They can test components and diagnose.

Step 10:

If the fan fails to start after the above checks, the blower motor may be faulty. A technician can remove power from the furnace and perform closed-circuit testing on the motor windings to check for electrical integrity. If the windings are compromised, motor replacement is required.

Step 11:

Check that the blower wheel is firmly attached to the motor shaft for direct-drive furnace fans. Setscrews can vibrate loose over time, causing the blower wheel to slip on the shaft. Tightening the setscrews securely or applying a thread-locking compound can help secure the connection.

Step 12:

With the blower wheel removed, technicians can also check the motor shaft for excess play. Motor shafts ride on oil-impregnated bushings that can wear out over time. Extra shaft play indicates worn bushings that will need replacement.

Step 13:

If the bearings, pulleys, and belts check out, examine the blower housing for damage. The scrolls that guide airflow around the blower can become bent, obstructing flow. The housing can also rust through over time, resulting in restricted airflow. A damaged housing will need to be repaired or replaced.

Step 14:

For older furnaces, have the technician examine the fan limit control. This safety switch prevents the fan from running at unsafe temperatures. If it fails to properly open the circuit at low temperatures, the control will need to be replaced.

Step 15:

On some furnace models, failure of the draft inducer fan can result in the blower fan not starting up. The control board needs input from the inducer proving switch to allow blower operation. If the inducer fan malfunctions, the blower won’t run.

By methodically working through these troubleshooting steps, you should be able to determine why a furnace fan isn’t starting and remedy the problem. In many cases, minor repairs or component replacements may be all that’s needed to get the fan spinning again.

FAQs

FAQ 1: How can I tell if my furnace fan is broken?

Some signs your furnace fan may be broken include:

- Lack of airflow coming from ducts during furnace operation

- Burning smells from overheating motor

- Loud noises or grinding sounds

- The fan not starting up when the heat turns on

- Intermittent fan operation

If you notice these or other unusual symptoms, it likely indicates an issue with the furnace blower fan requiring repair.

FAQ 2: Why does my furnace fan run all the time?

The furnace control board may be stuck in continuous fan mode if the fan remains constantly on. This setting allows independent fan operation without heat. Check your thermostat settings or furnace controls to remove it from continuous mode. A lousy thermostat signal or control board issue can cause continuous fan operation.

FAQ 3: Why is my furnace fan so loud?

Excess noise from a furnace fan often stems from an out-of-balance or damaged blower wheel. The wheel can warp, or debris can build up on blades over time. Loose, worn, or misaligned belts in belt drive systems can also cause excessive noise. Having a technician inspect and address these issues can quiet the fan.

FAQ 4: How often should furnace fans be replaced?

The expected lifespan for furnace fans varies based on usage and operating conditions. Typically, furnace fans last 10-15 years before needing replacement. Hard starts in cold weather and constant cycling put more wear on fan components. Routine maintenance extends the fan’s lifespan, like lubrication and belt replacement.

FAQ 5: Can I replace my furnace fan myself?

Replacing a furnace blower fan is generally not a DIY project for most homeowners. The job involves disconnecting power, removing the blower assembly, changing out the motor, and reinstalling the fan correctly. Adjusting fan speed settings requires specialized tools. Having an HVAC professional replace the furnace fan ensures proper installation and avoids safety risks.

Conclusion

Having your furnace fan not start when heat is called for can be inconvenient. However, identifying the root cause is typically more straightforward than you may think. Following basic troubleshooting steps helps narrow down whether electrical supply, belt/bearing issues, airflow blockages, or failed components prevent operation. Repairs like resetting breakers, changing filters, and replacing defective parts can often get the fan spinning again.

Don’t hesitate to hire a professional for more complex fan problems involving motors, controls, or wiring. Diagnosis and repair costs are usually far less than installing a new furnace. When deciphering the meaning of flashing lights during the charging process of your Shark battery, it is essential to consult the product manual or contact customer support for accurate troubleshooting guidance. Meanwhile, with proper troubleshooting, Flashing Lights, and quality repairs, your existing furnace fan has the potential to efficiently maintain a comfortable level of warmth in your home for years.